Specific Work Gloves: Features of Gloves Used in Construction, Automotive and Food Industries

Work gloves are essential in various industries to ensure safety and efficiency. Different sectors have specific requirements for hand protection, and gloves are designed accordingly to meet these needs. In this post, we will explore the features of gloves used in the construction, automotive, and food industries, highlighting how they cater to the unique demands of each field.

Construction Industry Gloves

In the construction industry, gloves are crucial for protecting workers from a wide range of hazards, including cuts, abrasions, impacts, and chemical exposures. The gloves used in this sector need to be robust and durable to withstand the harsh conditions of construction sites. They are often made from materials like leather, synthetic leather, and high-performance fabrics that provide excellent resistance to cuts and punctures. Additionally, construction gloves usually feature reinforced palms and fingers to enhance durability and grip, making it easier for workers to handle tools and materials securely.

Construction gloves also need to provide flexibility and dexterity, allowing workers to perform precise tasks without sacrificing protection. Some gloves come with padded or impact-resistant zones to protect against hand injuries caused by heavy machinery or falling objects. Moreover, many construction gloves are designed to offer weather resistance, ensuring that workers’ hands remain protected in various environmental conditions, such as rain, snow, or extreme heat.

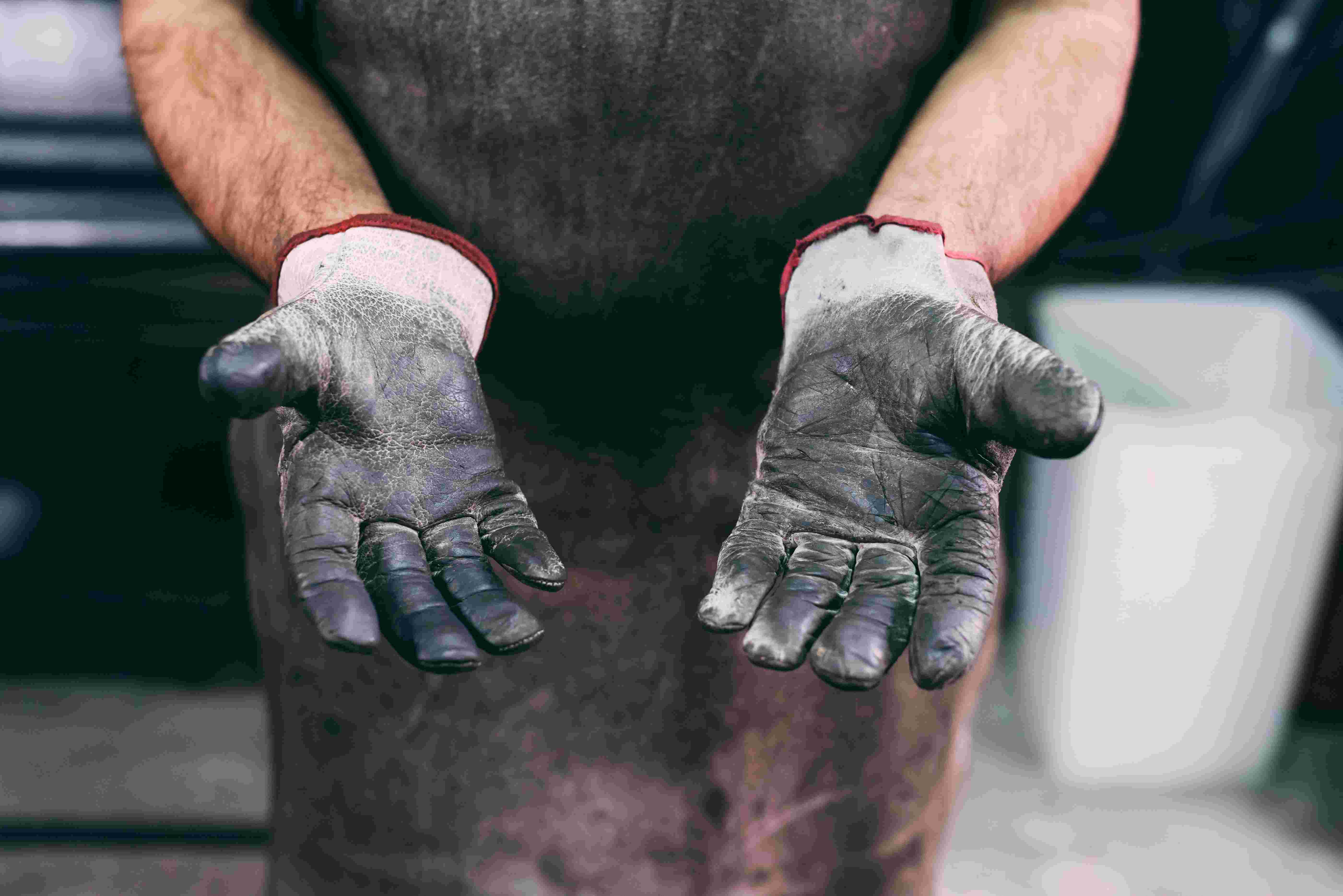

Automotive Industry Gloves

The automotive industry requires gloves that offer a balance between protection, dexterity, and tactile sensitivity. Workers in this sector often handle small parts, tools, and machinery, requiring gloves that allow for precise movements while providing adequate protection from cuts, abrasions, and chemical exposures. Nitrile gloves are particularly popular in the automotive industry due to their excellent chemical resistance, protecting workers from oils, greases, solvents, and other hazardous substances commonly encountered in automotive repair and maintenance.

In addition to chemical resistance, automotive gloves need to provide a good grip to handle tools and parts effectively. Textured surfaces or specialized coatings on the palms and fingers can enhance grip, even in oily or wet conditions. Furthermore, gloves used in this industry often incorporate features like anti-vibration padding to reduce hand fatigue and prevent long-term injuries associated with repetitive motions and the use of power tools.

Food Industry Gloves

In the food industry, hygiene and safety are paramount. Gloves used in this sector must meet stringent standards to ensure that they do not contaminate food products. Disposable gloves, such as those made from nitrile, latex, or vinyl, are commonly used to maintain high levels of hygiene. These gloves are designed to be single-use, reducing the risk of cross-contamination between different tasks or food items.

Food industry gloves need to be free from harmful chemicals and additives that could leach into food products. They are often powder-free to prevent the transfer of residues to food surfaces. Additionally, these gloves

should provide a comfortable fit and good tactile sensitivity, allowing workers to handle food items delicately and efficiently. Some gloves used in the food industry are also designed to be resistant to punctures and tears, ensuring they remain intact during use and provide consistent protection.

Beybi Plastik, since its establishment in 1949; operates in the field of personal protective work safety gloves, examination gloves production and sales, sterile surgical gloves and medical consumables sales and marketing.